Commercial roofing is one of the most critical components of any commercial building, protecting assets, occupants, and operations from the elements. Over time, roofs deteriorate due to weather exposure, foot traffic, and normal wear and tear. When a roofing system nears the end of its useful life, building owners and facility managers face a pivotal decision: invest in a full roof replacement or opt for a roof coating system. While replacement offers a brand-new membrane and extended warranty, roof coatings deliver significant benefits in terms of cost, sustainability, and downtime. In this post, we’ll explore the advantages of commercial roof coatings versus full replacement, helping you determine the best path forward for your facility.

What Is Commercial Roof Coating?

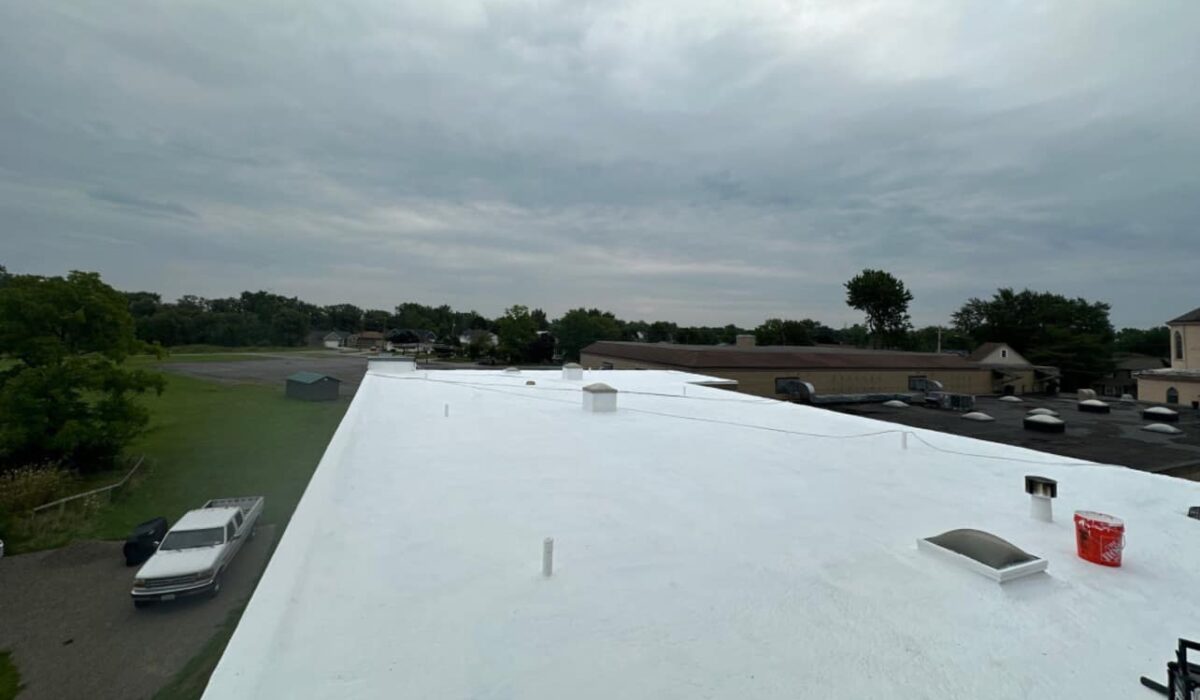

Commercial roof coatings are liquid-applied membranes that adhere to existing roofing surfaces—such as single-ply membranes (TPO, PVC, EPDM), metal, concrete, or built-up roofing. Once applied, the coating cures to form a seamless, waterproof layer that restores weatherproofing, enhances reflectivity, and extends the life of the roof without removing the existing membrane.

- Single-ply application: No seams or fasteners, reducing leak points.

- Multiple coating types: Silicone, acrylic, polyurethane, and asphalt emulsions.

- Reflective finishes: Often available in white or light colors to reduce heat absorption.

- Low volatile organic compounds (VOCs): Many products are formulated for environmental compliance.

Cost Comparison: Coating vs. Replacement

| Expense Category | Roof Coating (per sq ft) | Roof Replacement (per sq ft) |

|---|---|---|

| Material | $0.75 – $1.50 | $4.00 – $8.00 |

| Labor | $0.50 – $1.00 | $2.00 – $4.00 |

| Tear-off & Disposal | N/A | $1.00 – $1.50 |

| Total Installed Cost | $1.25 – $2.50 | $7.00 – $13.50 |

Coatings require fewer materials and less labor, translating to savings of up to 80% compared to a full replacement, plus no disposal fees.

Benefits of Roof Coatings

1. Cost Savings and ROI

- Reduced upfront capital: Lower initial investment.

- Quick payback: Energy savings from reflective coatings often pay for themselves within 2–4 years.

- Extended service life: Quality coatings add 8–15 years of service life.

2. Sustainability and Environmental Impact

- Reduced landfill waste: Coatings preserve existing materials, avoiding disposal.

- Improved energy efficiency: Reflective coatings can lower roof surface temperatures by 50–70°F, cutting cooling costs by 10–20%.

- Low-VOC formulations: Many coatings meet EPA and air-quality standards.

3. Minimal Disruption to Operations

- Fast installation: Often completed in days, not weeks.

- No building downtime: Crews work around business hours with minimal noise.

- Continuous protection: The existing membrane stays intact throughout.

4. Enhanced Roof Performance

- Seamless waterproofing: Eliminates laps and fastener holes.

- UV resistance: Additives shield against ultraviolet degradation.

- Flexibility and crack bridging: Elastomeric coatings expand and contract with temperature swings.

When Is Roof Replacement Necessary?

While coatings offer numerous advantages, replacement is still the best choice under certain conditions:

- Severe structural damage: Rot, rust, or delamination of the deck or substrate.

- Multiple failed patches or layers: Chronic failures may warrant a fresh start.

- Warranty requirements: Some membrane warranties require a new substrate.

- Building use changes: New equipment loads or green-roof conversions may need structural upgrades.

A professional roofing inspection will help you weigh the trade-offs and choose the right path.

Key Considerations for a Successful Coating Project

1. Roof Assessment

- Moisture scanning: Detect hidden water in insulation layers.

- Substrate integrity: Ensure the membrane is sound.

- Surface preparation: Power-wash to remove dirt and loose material.

2. Product Selection

- Climatic compatibility: Choose silicone for ponding water, acrylic for moderate climates.

- Reflectivity requirements: Verify local SRI mandates.

- Manufacturer reputation: Pick well-supported products with solid warranties.

3. Installer Qualifications

- Certified applicators: Use manufacturer-approved contractors.

- Climate experience: Regional weather impacts adhesion and cure time.

- Project references: Review case studies or local installations.

4. Warranty and Maintenance

- Manufacturer warranty: Often 10–20 years, prorated.

- Maintenance plan: Annual inspections and minor repairs.

- Re-coating schedule: Plan a mid-term re-coat at 8–10 years.

Real-World Example

A 100,000 sq ft warehouse in Texas faced high summer cooling costs. Instead of a $900,000 tear-off, the owner invested $180,000 in a silicone roof coating. Energy bills dropped by 18%, saving $32,000 per year. With deferred replacement costs and reduced HVAC wear, payback occurred in under five years—backed by a 15-year warranty.

Conclusion

Choosing between roof coating and full replacement involves balancing cost, performance, sustainability, and long-term strategy. Coatings deliver dramatic savings, eco-friendly credentials, minimal disruption, and extended service life. However, structural issues or warranty conditions may necessitate replacement. Partner with a qualified consultant, perform thorough assessments, and select the right system to protect your facility and budget for years to come.